Testing/Case Studies

Rhino Carbon Fiber Independent Testing/Case Studies

Rhino Carbon Fiber is independently tested by third party vendors to ensure it is the highest quality products available. Please review the test results and an engineering case study to learn how strong Rhino Carbon Fiber is. The results of the testing are below.

DESCRIPTION

Two sets of carbon fiber samples were received for room tempaerture tention testing. They were identified as Rhino® Fiber Horizontals.

MECHANICAL

Two sets of tensile specimens, with a nominal gage width of 1.0 inches, were received already prepared by the client. Prior to testing it was noted that the specimens have uneven gage sections, jagged edges, areas of non-existant fibers (epoxy only), and uneven layering. Testing was performed at room temperature on a servo-hydraulic test stand with guidance from ASTM D3039-08. Specimens were loaded in displacement control at a rate of 0.05 in/min until rupture.

Table 1 (Carbon Fiber Horizontals)

| Sample | Ultimate Tensile Strength (PSI) | |

| Rhino Carbon Fiber | ||

| 1 | 48,030 | |

| 2 | 54,200 | |

| 3 | 44,310 | |

| 4 | 46,260 | |

| 5 | 51,310 | |

RESULTS

The average ultimate tensile strength for Rhino Carbon Fiber equals 48,822 psi. Through tensile testing we are able to determine that Rhino Carbon Fiber Horizontals are substantially stronger that the competition.

DESCRIPTION

One set of carbon fiber samples were received for room temperature tension testing. They were identified as Rhino® Carbon Fiber Verticals.

MECHANICAL

One set of tensile specimens, with a nominal gage width of 1.0 inches, were received already prepared by the client. Prior to testing it was noted that the specimens had uneven gage sections, jagged edges, areas of non-existent fibers (epoxy only), and uneven layering. Testing was performed at room temperature on a servo-hydraulic test stand with guidance from ASTM D3039-08. Specimens were loaded in displacement control at a rate of 0.05 in/min until rupture.

The sample results are presented in Table 01.

Total results from test are presented in Table 02 with comparative results from Fortress Stabilization System’s website (www.fortressstabilization.com/weavetest.php).

Table 1 (Carboon Fiber Verticals)

| Sample | Ultimate Tensile Strength (PSI) | |

| Rhino Carbon Fiber | ||

| 1 | 49,890 | |

| 2 | 64,200 | |

| 3 | 53,700 | |

| 4 | 44,320 | |

| 5 | 42,240 | |

| 6 | 56,510 | |

| 7 | 37,610 | |

| 8 | 46,670 | |

| 9 | 63,430 | |

| 10 | 53,660 | |

| 11 | 45,320 | |

| 12 | 58,070 | |

| 13 | 48,020 | |

| 14 | 61,560 | |

| 15 | 41,530 | |

| 16 | 57,590 | |

| 17 | 40,920 | |

| 18 | 52,980 | |

| 19 | 54,530 | |

| 20 | 58,670 | |

Table 2 (Carboon Fiber Verticals)

RESULTS

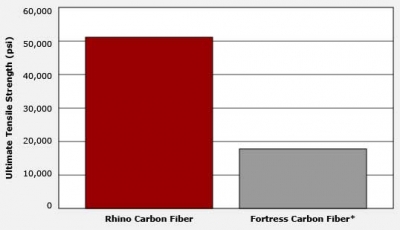

The average ultimate tensile strength for Rhino Carbon Fiber equals 51,571 psi.

The average ultimate tensile strength for Fortress Carbon Fiber equals 18,136 psi.

Through tensile testing we were able to determine that Rhino Carbon Fiber Verticals are substantially stronger than the competition.

*Results pulled from the Fortress Stabilization System's website

(fortressstabilization.com/weavetest.php).

DESCRIPTION

Two sets of composite samples were received for lap shear testing in accordance with ACI 440.3R-04.

MECHANICAL

All samples were conditioned for a minimum of 40 hours at 20 ± 3°C and 50 ± 5% relative humidity. All samples were tested in similar conditions.

LAP SHEAR TESTING

Five samples were received for lap shear testing in accordance with ACI 440.3R-04 which in turn referred to ASTM D3039. The samples were tested in the same condition that they were received in. After recieving the samples, it was noted that they had uneven and jagged gage sections. The lap area of the samples was uneven and the thickness varied. The samples were then tested on a servo-hydraulic test stand at a crosshead speed of 0.05 millimeters per second.

The sample results are presented in Table 01.

Table 1 (Lap Shear Results)

| Sample | Overlap Dimensions (in) |

Shear Strength (psi) |

Failure Strain |

| 1 | 1.034 x 5.55 | 369 | Tension Failure |

| 2 | 1.060 x 6.00 | 156 | Tension Failure |

| 3 | 0.960 x 5.36 | 342 | Tension Failure |

| 4 | 1.085 x 5.05 | 324 | Tension Failure |

| 5 | 1.061 x 5.76 | 218 | Tension Failure |

| Average | -- | 282 | -- |

| St. Dev. | -- | 90.7 | -- |

RESULTS

Each of the samples did not fail in the lap shear area.

Click to read the report

Click to read the report.